3D Printed Prosthetics Parametric House

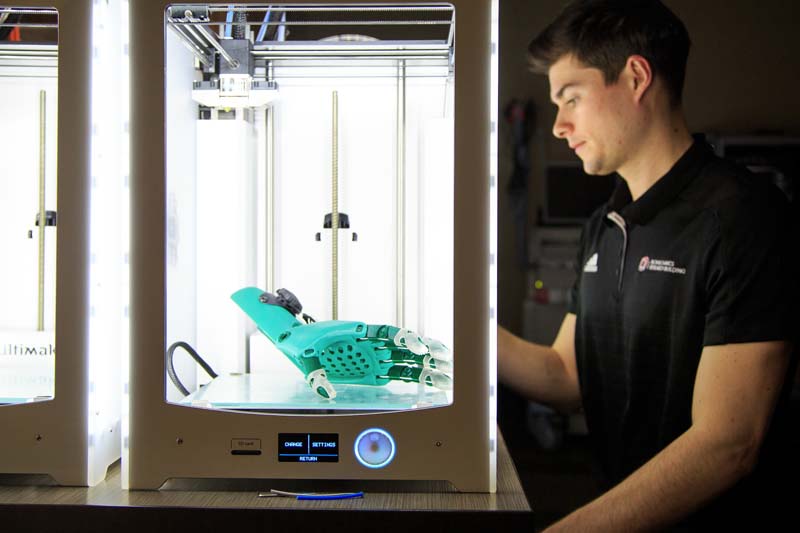

Step 3: 3D Printing. Once finalized, the prosthesis design is sent to 3D printers, which print layer-upon-layer of material to create a bonded, solid object. This technique enables the printing of highly complex structures in a very short period, something that would not be feasible using manual production processes.

3D Printed Prosthetics with Little Assembly Show Promise for Greater Use in Developing Countries

3D Printed Prosthetics: Cheaper, Better, More Versatile. by Alexander Klarmann. Published Jul 12, 2015. Advertisement. 3D printing makes prosthetics much more affordable. Also, you can add electronics. This gives a 3D printed prosthesis a whole new dimension.

Uso de impresoras 3D para la creación de prótesis

The Most Common 3D Printed Prosthetics of 2023. by Lauren Fuentes. Updated Jan 5, 2023. Thanks to 3D printed prosthetics, many lives are changing for the better. Read on to learn about the most promising projects! Advertisement. Thanks to 3D printed prosthetics, many lives are changing for the better. Read on to learn about the most promising.

Top 15 prosthetics made with 3D printing Bitfab

The result is that braces and artificial limbs are among the most desperately needed medical devices. However, technology may be hurtling to the rescue - in the shape of 3D printing. Slowly but.

LowCost Flexy Hand 3DP Prosthetic 3D Printing Industry

10.1 Introduction. 3D printing in maxillofacial prosthetics has evolved over the past few decades into a global standard of care in contemporary clinical practices. While direct access to 3D acquisition and printing technologies varies from clinic to clinic and from country to country, the pursuit to define digital workflows utilizing 3D.

3D printing of prosthetics ConnSENSE Report

The HP Jet Fusion 5600 Series 3D Printing Solution is currently available with HP 3D High Reusability PA 12 enabled by Evonik. Data courtesy of Unlimited Tomorrow. Discover how 3D printing for Orthotics and Prosthetics can produce customized, quality 3D printed devices designed to help enhance patient comfort. Learn More!

NU Team to Research, Design Next Generation of 3DPrinted Prostheses News University of

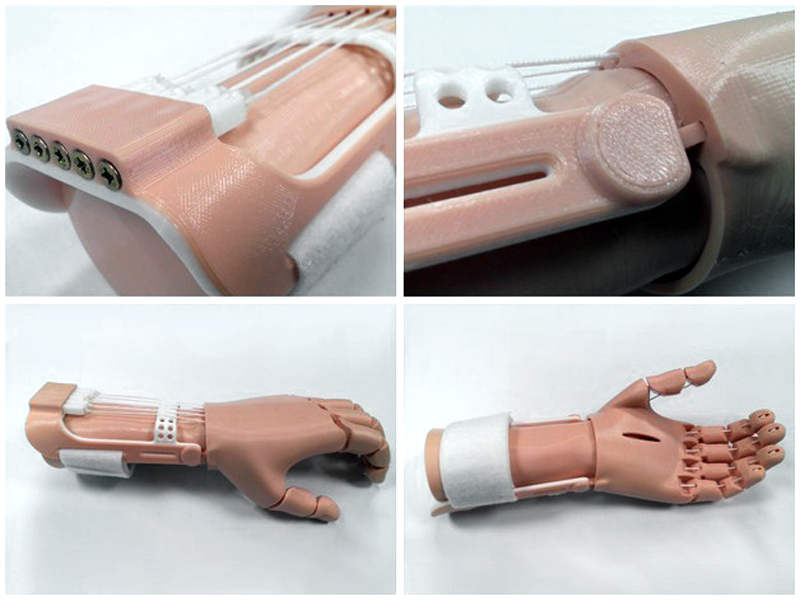

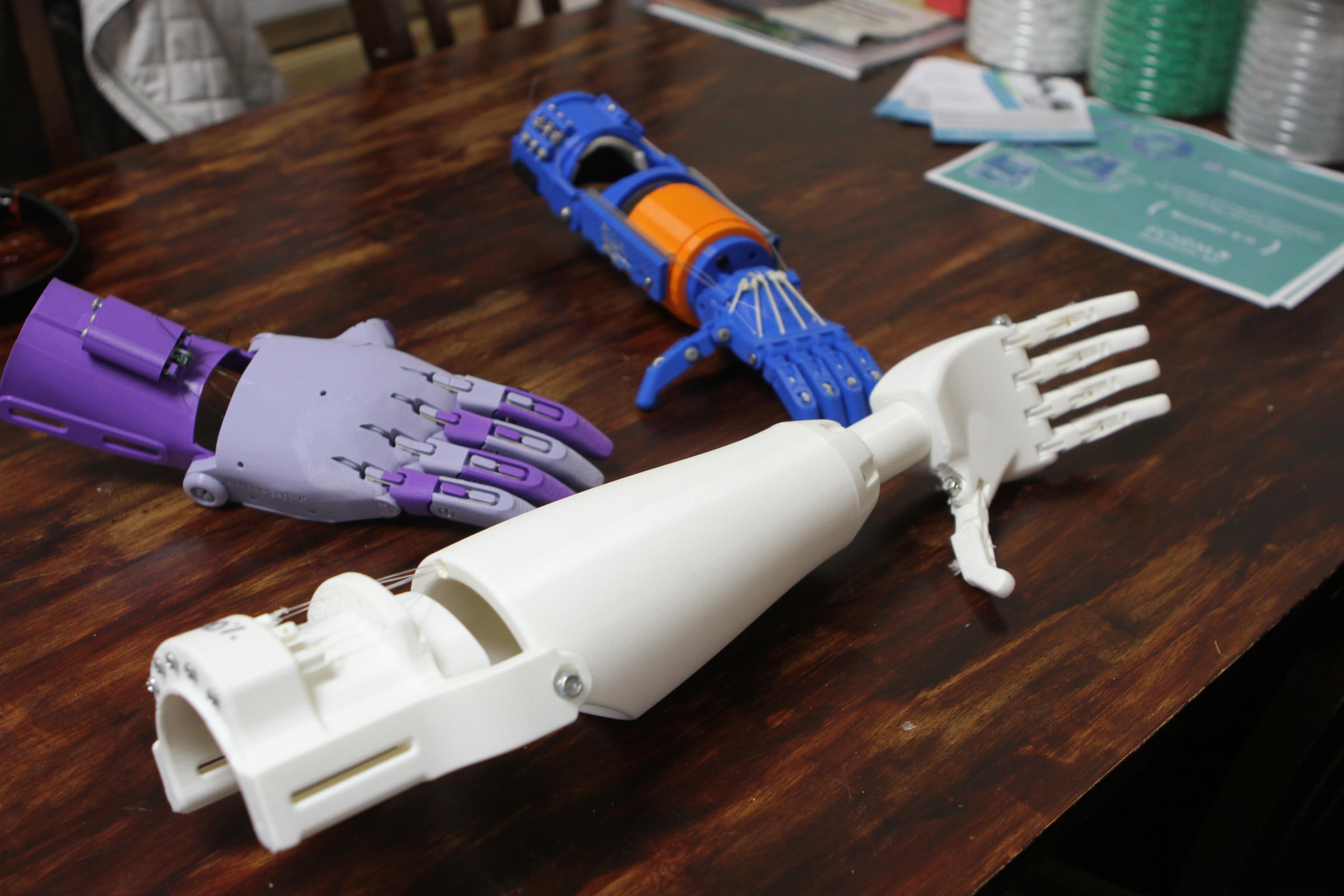

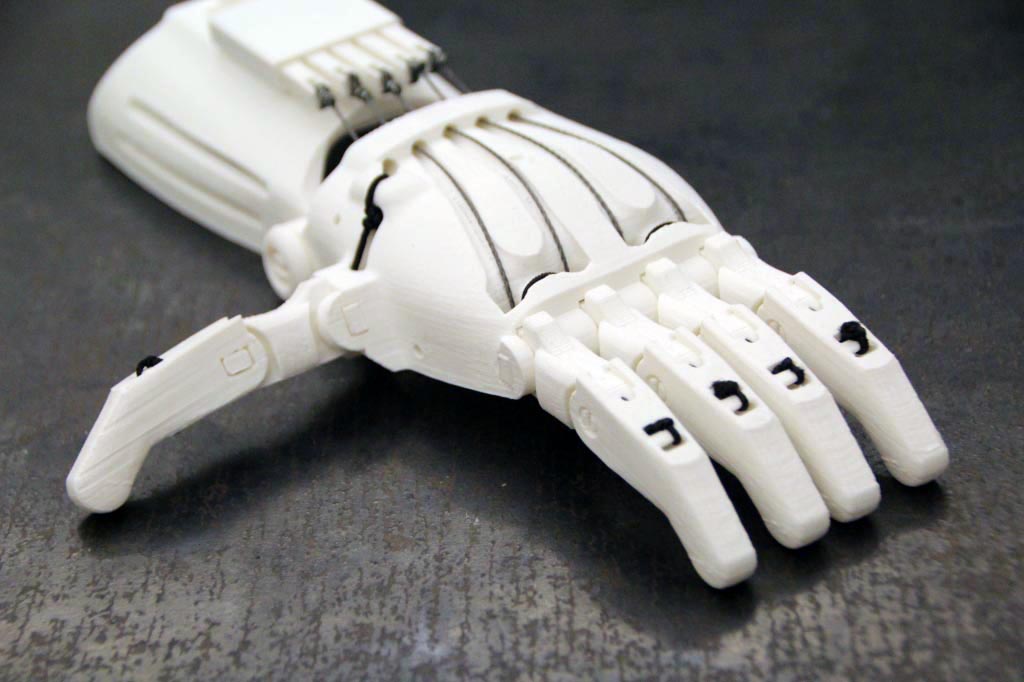

Prosthetics 3D printing is the use of 3D printers to design and create artificial, wearable body parts such as legs, hands, and arms. It is a relatively new method compared to the traditional method of production. The materials used in creating 3D printed prosthetics are accessible and lightweight, making the process suitable for producing.

30 for custommade prosthetics? With 3D printing, it’s possible Create

The 3D printed prosthetic. The Open Bionics hand is suited for trans-radial amputees: people that still have an elbow joint but miss anywhere from their hand upwards. The prosthetic works through sensors that are placed on the wearer's muscles. These send out an electric signal that allows the hand to move when specific muscles are flexed.

3D Printed Prosthetic Hand YouTube

This prosthesis is based on myoelectric technology and is made with 3D printing technologies as well as adding the famous Arduino 'open source' plate which, through sensors, can feel the muscle of the user and allows him/her to make different grip movements. The Youbionic has already been released to the market with a price of €1.200.

3D Printers Give Way To New Generation Of Inexpensive Prosthetics 90.5 WESA

There are various 3D printing techniques available for O&P applications : FDM (Fused Deposition Modelling), also known as FFF (Fused Filament Fabrication), is based on thermal extrusion: A thermoplastic filament is melted and put on the building platform. Layer-by-layer the orthopaedic device is created. SLA (Stereolithography) and DLP (Digital.

Student Startup ‘Limber’ Makes 3DPrinted Prostheses Affordable and Accessible

August 31, 2023. The potential for 3D printed prosthetics to increase the quality of life for many at a fraction of the cost of traditional prostheses is becoming clearer and clearer every day. A study from 2021 showed that up to one-third of Americans refuse healthcare due to the high costs. And using additive manufacturing to produce them.

Top 15 prosthetics made with 3D printing Bitfab

Isabela Castillo began building 3D-printed prosthetic hands as a high schooler in Mexico City. When she came to Northeastern University, she and her friends turned the project into an engineering club with big ambitions. Schuyler Velasco. Isabela Castillo works on a 3-D printed prosthetic hand in the EXP Makerspace on the Boston campus.

Official Creality3D® Store FDM,LCD 3D Printer, Part Accessories UK in stock

Researchers also decreased the weight of the prosthetic by using cutting-edge 3D-printing materials. Most of their new prosthetics are made from a combination of nylon and nylon filled with chopped carbon fiber. By 3D-printing with the two materials, the team can vary the stiffness of the limb, making the foot more flexible, for example.

List of Top Ten Best 3d Printer For Prosthetics 2023 Reviews

Paul Hanaphy March 09th 2021 - 11:59am 0 0. 0. Scientists from the Israel Institute of Technology have developed an automated production line for 3D printing low-cost customized prosthetic limbs.

A new innovation in the 3D printing of Prosthetics 3Dnatives

Costs of 3D Printed Prosthetics. According to the American Orthotics and Prosthetics Association, the average prosthetic costs between $1500 to $50,000. It depends on the part of the body being replaced. For instance, a prosthetic leg can range between $5,000 to $50,000. However, this is not a one-time cost.

Intel Volunteers Build 100 Prosthetic Hands for Haiti in 2 Hours 3D Printing Industry

Naked Prosthetics and Resin 3D Printing. Based in the United States, Naked Prosthetics (NP) is a company dedicated to the development of functional prosthetic devices for hands and fingers. To do so, they rely on resin 3D printing, specifically stereolithography, with which they create these customized models adapted to the needs of each user.

- Appcc Industria Carnica Castilla Y Leon

- Cual Es El Valor De Una Potencia De Base 0

- Resumen Deportivo De La Coruña

- Vision De Nieve

- Camara De Industria De Costa Rica

- Con Las Alas De La Furia Lol

- Ferias De Marisco En Galicia En Agosto 2021

- Rodillo Para Pintar Con Dibujos

- Capacitive Soil Moisture Sensor Arduino

- Chloe Moretz Ass Hole Bikini