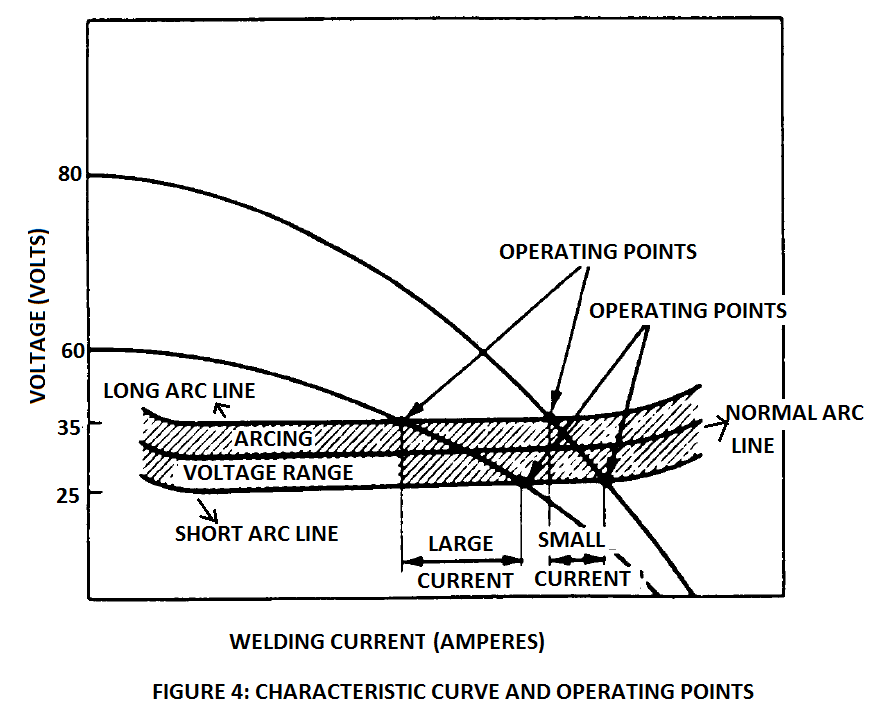

Arc Welding With Constant Current

Welding Temperatures; Welding or Melting Process Temperature (°C) Oxygen hydrogen torch: 1450: Combustion furnace: 1700: Aluminium-iron powder: 2800: Electric furnace: 3000: Oxygen acetylene torch: 3500: Direct electric arc: 4000: Electron-beam welding > 10000: Laser-beam welding > 10000: Plasma arc welding: 33000: Related Topics Miscellaneous.

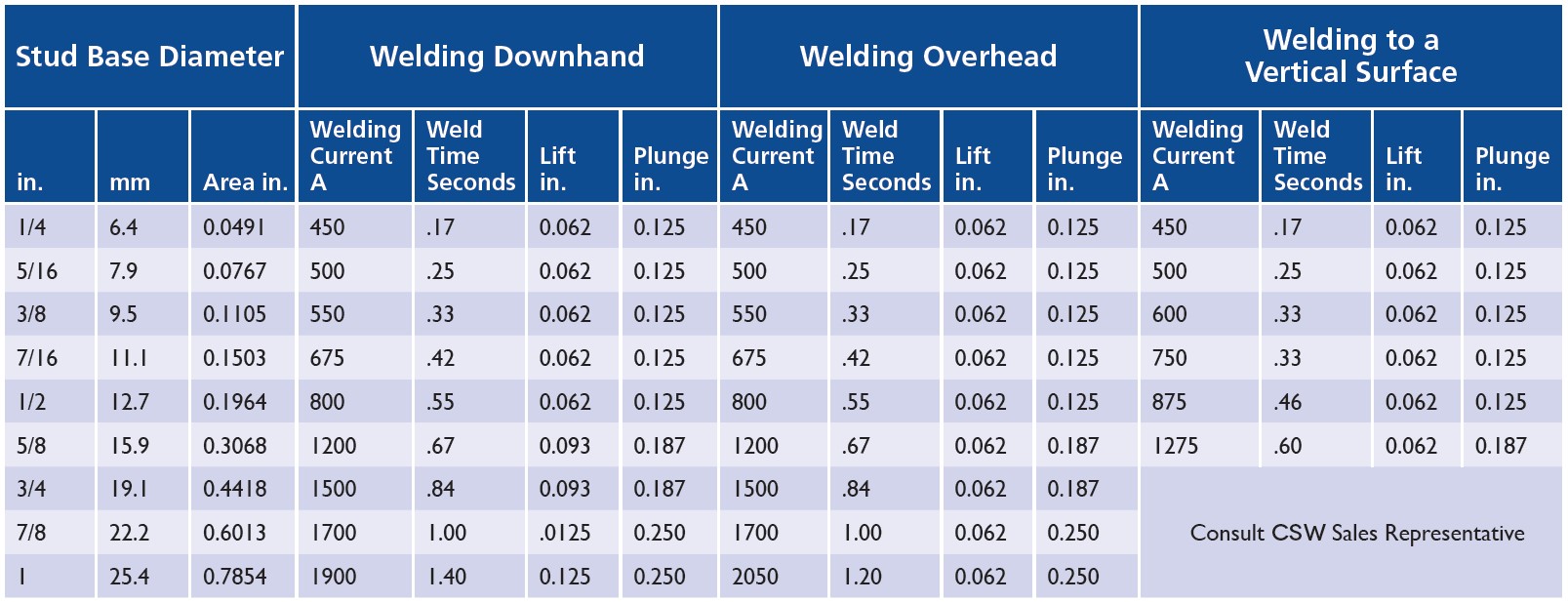

Arc Stud Welding Complete Stud Weld

The temperature of MIG welding, also known as Gas Metal Arc Welding (GMAW), primarily depends on the specific materials being welded and the welding parameters. While the actual temperature during MIG welding can vary, the interpass temperature guidelines for MIG welding typically recommend keeping it below 150°C (302°F) to avoid excessive.

Welding

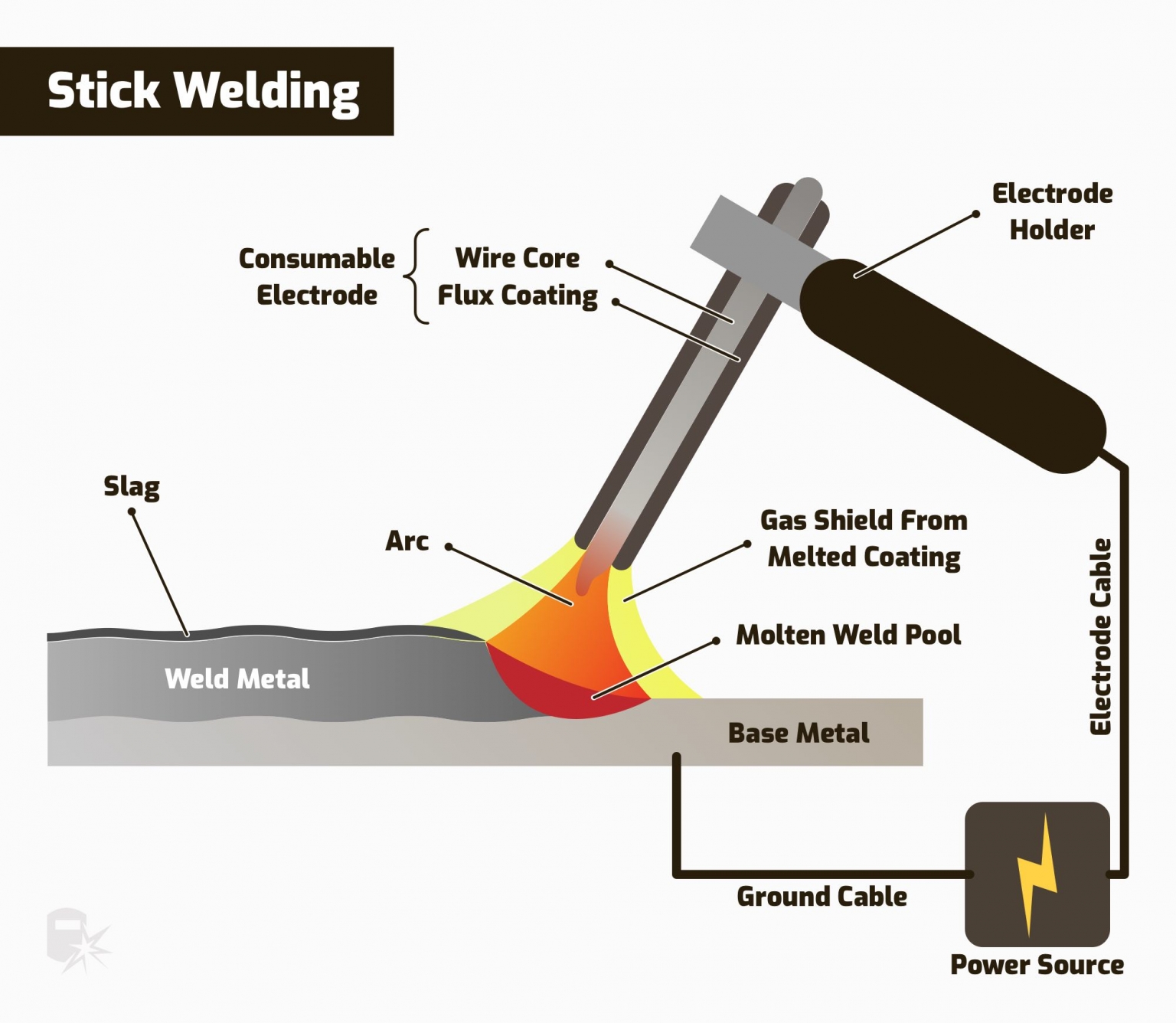

Arc welding is a fusion welding process used to join metals. An electric arc from an AC or DC power supply creates an intense heat of around 6500°F which melts the metal at the join between two work pieces.. Because the metals react chemically to oxygen and nitrogen in the air when heated to high temperatures by the arc, a protective.

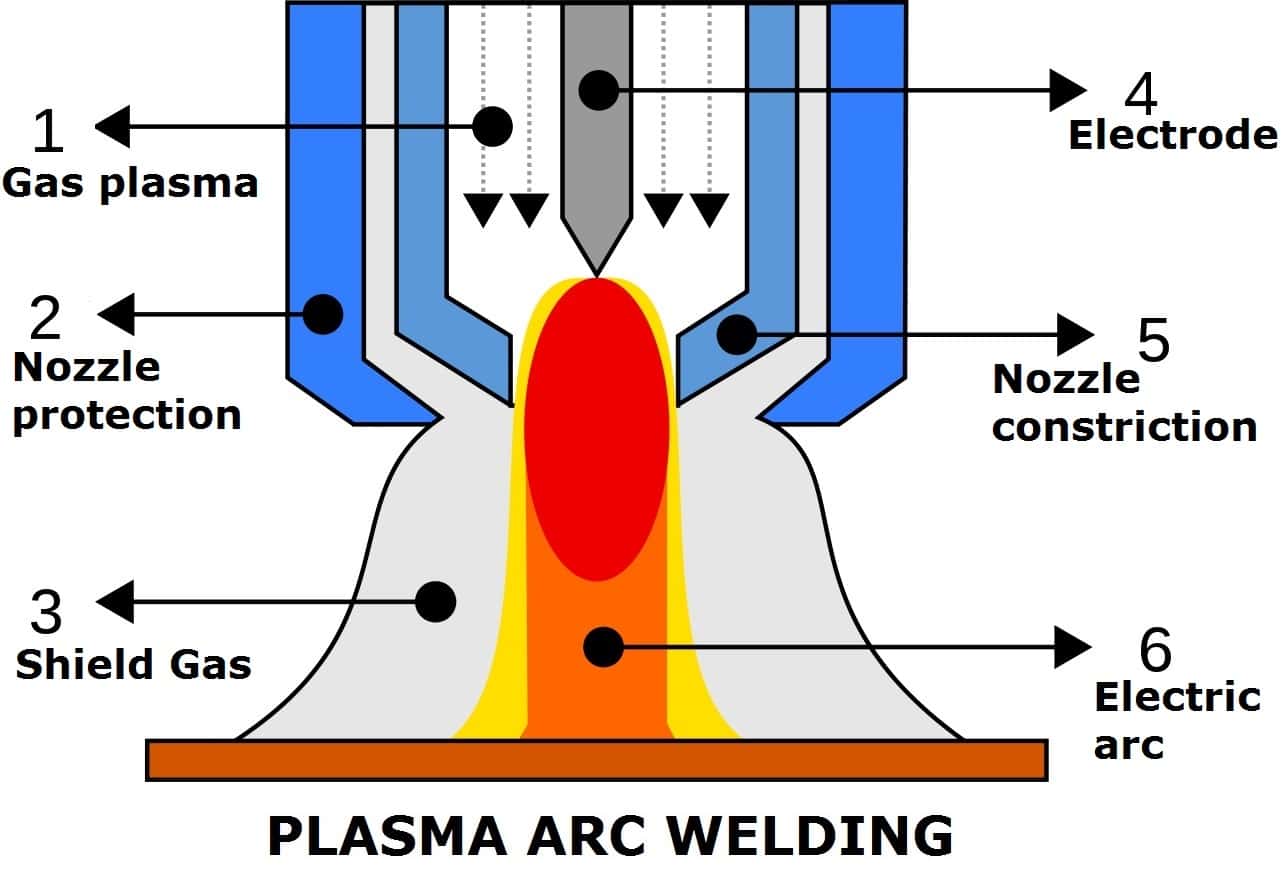

Plasma Arc Welding Definition, Construction, Working Principle

Proper Temperature When Arc Welding. Part of the series: Arc Welding Tips For Beginning Welders. Learn how to use proper welding temperatures to improve stic.

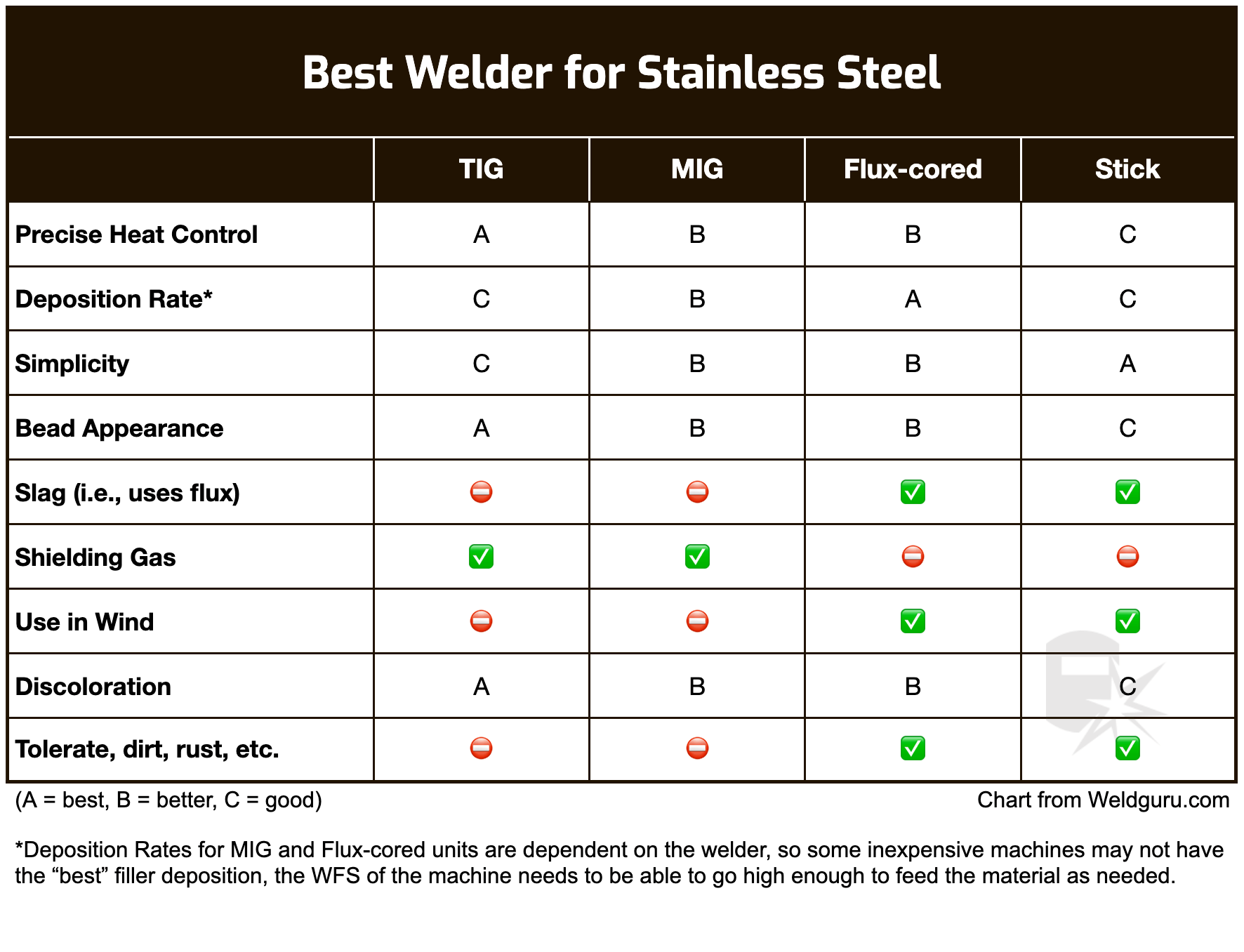

How to Weld Stainless Steel A Complete Guide

Manual Metal Arc Welding (MMA) 0.8 Cored Wire Welding/Flux Cored Arc Welding (FCAW) 0.8 Metal Active Gas (MAG) Metal Inert Gas (MIG) 0.8 Tungsten Inert Gas (TIG) 0.6 Example: I'm doing Manual Metal Arc Welding (Electrode / stick welding). My Amperage is 120 Amp, Arc voltage 30 Volt, Welding speed 150mm/min EN Heat input =

Temperature welding cycle for TIG welding with different preheating

The temperature of a welding arc ranges from 5,000° to 6,000° Fahrenheit (2,760° to 3,316° Celsius). However, this is only an average value, and the actual temperature varies depending on the type of welding process and other factors we discuss below.

Carbon Electrode Arc Welding Process with Non Consumable Carbon

The temperature of MIG welding can reach up to 6,500 degrees Fahrenheit (3,593 degrees Celsius), which is hotter than the surface of the sun! 2. During MIG welding, the temperature at the welding arc can become so intense that it can melt through solid metals, including steel. 3. When MIG welding, the electrode wire is melted by an electric arc.

Different zones in cast iron weldment and corresponding temperature in

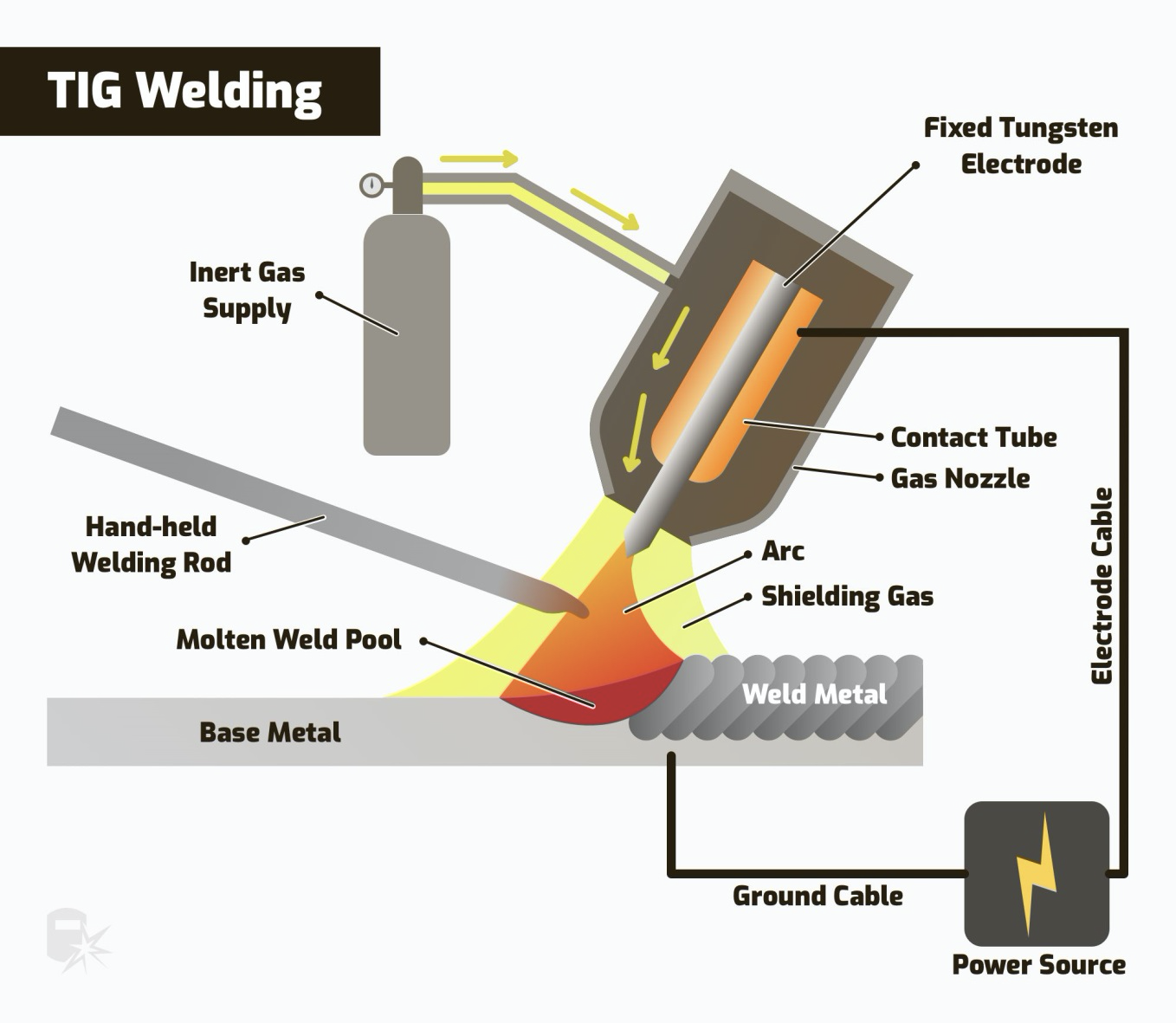

The temperature created during welding is known as the arc temperature and it varies depending on the type of welding process being used. Below are the temperature listed for different welding arc types: Gas Welding, Acetylene Flame: 5500°F (3038°C), Stick Welding (SMAW): 3200°F (1760°C ), TIG Welding: 3400-4500°F (1871-2482°C),

(PDF) Effect of Torch Angle on Arc Properties and Weld Pool Shape in

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals.. When subjected to temperatures around 700 °C (1,300 °F) for too long a time,.

Arc welding for beginners

A welding arc typically has a temperature of 6500-10,000˚F. However, a plasma arc can reach 50,000˚F! Understanding the heat generated by a welding arc is crucial for both professionals and hobbyists in the field.

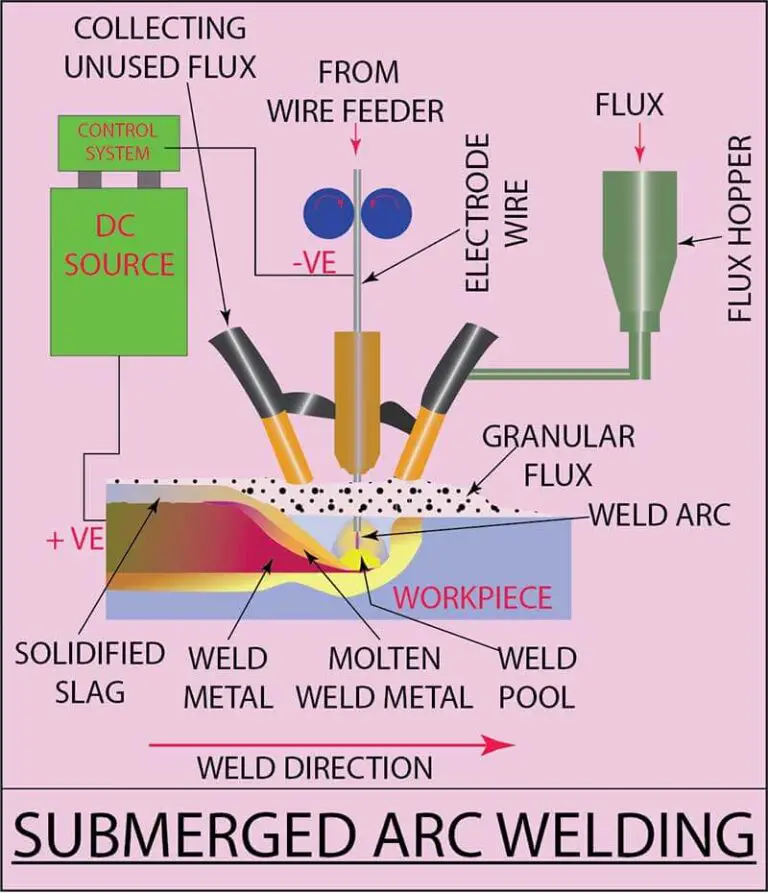

Insider's Guide to Submerged Arc Welding (SAW) Insider

This paper presents a state-of-the-art critical review of the thermal and structural modelling of the arc welding process. During the welding process, high temperature in the welding zone leads to generation of unwanted residual stresses and results in weld distortion.

Gas Tungsten Arc TIG Welding (GTAW) Baker Technical Institute

Moreover, the studies by Liu et al. [15] and Yuan et al. [20] showed that large WRS were distributed on the bottom surface of deck near the area of both inside weld and outside weld by double-sided arc welding. Based on the temperature measurement and simulation results (Fig. 11, Fig. 13), it is deduced that the local WRS is only related to its.

Welding temperatures (maximum temperatures measured during the welding

What Is the Temperature Range of an Arc Welding Process? The temperature of the electric arc in an arc welding process can be in the range of 3500 °C up to more than 20,000 °C! Although the temperature is very high, it is focused on a very small area of the metal surface. The high temperature of the arc means that the melting point of the.

Welding Processes Boiler World Update

Temperature-indicating crayons come in a range of temperature ratings. A typical structural steel welder or weld inspector should keep crayons rated at 150 F, 225 F, 300 F, 400 F, and 450 F around at all times. (It's hard to keep the 32 F, 50 F, and 70 F around, even in my neck of the woods!)

Arc Welding Explained What Is It & How Does It Work? Weld Guru

Thermal analysis is one of the cardinal studies essential for arc welding processes. Thermal field and temperature distribution in arc welds affect the quality of welds as they govern the microstructural and thermo-mechanical properties. Therefore, thorough understanding of the thermal behaviour in arc welds is an absolute necessity. Significant efforts have been made in the past to determine.

Thermal and structural modelling of arc welding processes A literature

1 Arc Initiation. Arc welding processes is based on application of heat generated by an arc for melting the faying surfaces of metals to be joined. Initiation of the welding arc is the first step in direction of developing a fusion weld. There are two most commonly used methods to initiate an electric arc in welding processes, namely touch.

- Fruta Morada Pequeña Nombre

- Hotel St Brelade S Bay Jersey

- Gimnasio En Parla Con Piscina

- Codigo Postal San Rafael Mendoza

- Como Una Flor De Selena

- Vestido Azul Electrico Combinar Zapatos

- Reparar Tapizado Techo Coche Sin Desmontar

- Porta Rollo Papel Higienico Acero Inoxidable Quios De Pared

- Como Purgar Un Sistema De Combustible Diesel

- Clinica Del Pilar Trabaja Con Nosotros