Carbon Fibre & Lightweight Components BadAss PowerSports

Development and future of carbon fibre in the boating industry. Composite fibre reinforced plastic (FRP) materials have been used in boat building for over 50 years. The first boats produced in fibreglass and polyester laminating resin using the hand lay-up process date from the 1970s. The increased use of composite materials as a result of.

Carbon Fiber 3D Printing The Ultimate Guide All3DP Pro

Fiber-reinforced polymer (FRP) composite material has predominant applications in the marine environment over traditional materials because of its superior mechanical properties, design flexibility, high strength-to-weight ratio as well as notable resistance to corrosion. These properties are very well supported by FRP composite materials in various applications in the marine environment.

Researchers Find New Way to Recycle Carbon Fibre

Manufactured with glass and carbon fiber composites, the foiler enables a smoother ride, higher speeds and longer range in up to 1.5-meter waves. In testing, the 11.5-meter prototype demonstrated 90% improved energy efficiency when compared to fossil fuel counterparts and has zero greenhouse gas (GHG) emissions. Artemis Technologies will test.

Recovering Carbon Fiber from Finished Composites Interview with Douglas Griffin Composites

Carbon fiber allows ships to make gains in speed and stability. Resistance to ageing, impact, corrosion, and mechanical fatigue significantly improves a vessel's safety and durability. From an environmental viewpoint, weight reduction reduces a vessel's energy consumption and, consequently, its CO2 emissions.

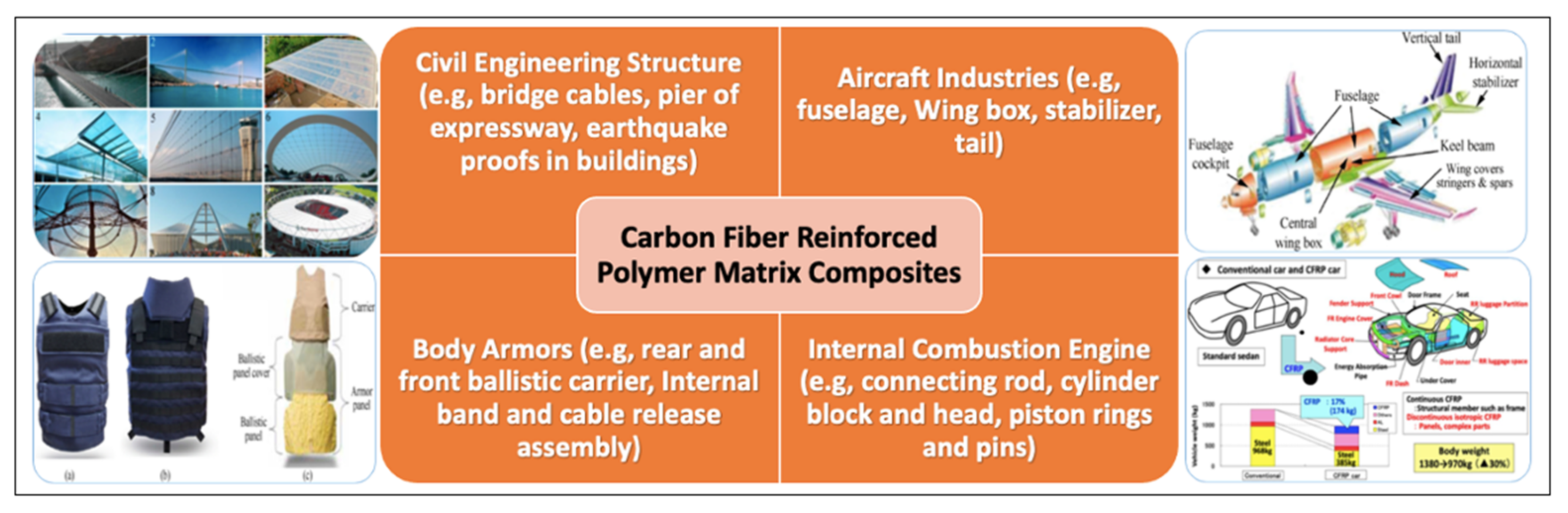

Applications of Carbon FiberReinforced Polymer Composites Encyclopedia MDPI

The history of carbon fibres and CFRPs is discussed over four representative periods including their early development (1950-60's), growth of carbon fibre composites industry (1970-80's), major adoption of carbon fibre composites (the first wave, 1990-2000's), and expanded use of carbon fibre composites (the second wave, 2010's and beyond).

Carbon Fibre Manufacturing Specialists Carbon Fibre Composites Ltd

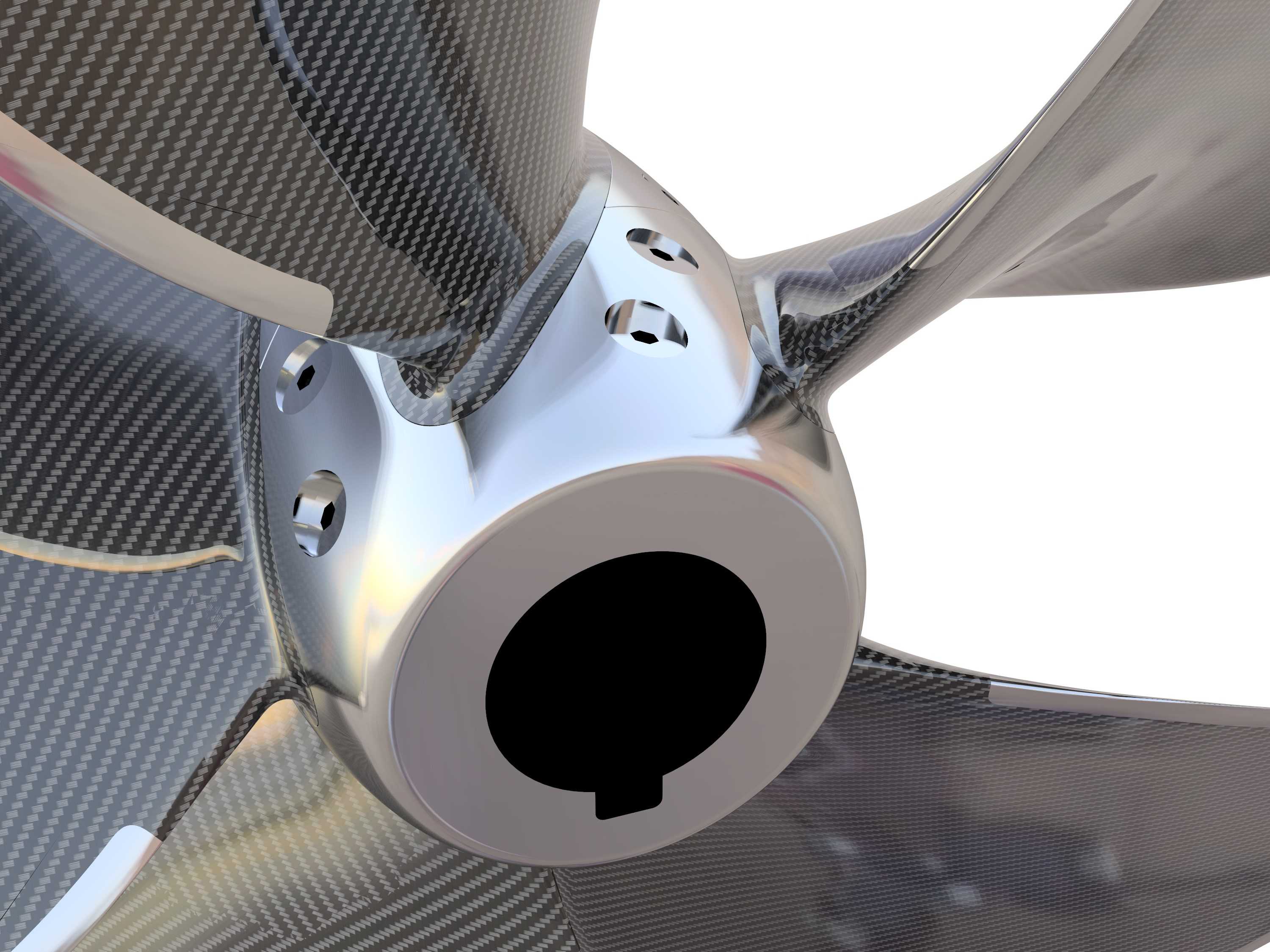

Tenax™ carbon fiber for marine environments. Tenax™ carbon fiber from Teijin is used in many marine applications, including masts, sail cloths, hulls, superstructures, drive shafts, and propellers. Lightweight and versatile carbon fiber allows marine vessels to make significant gains in speed, efficiency, and stability, while an enhanced.

漂亮的花纹

Carbon fibre composites came of age in the aerospace industry. Their true worth was recognise many years ago when aerospace engineers saw the weight savings that could be made compared with traditional materials like metals. Table 1 illustrate this quite clearly by showing the structural efficiency of a variety of materials that might be used.

Carbon Fibre — Engineering Solutions

The Impact of Carbon Fiber on Speed and Performance. Carbon fiber, the undisputed champion in boat hull speed and performance. It's as if your boat sprouted wings while others are left paddling aimlessly. The mind-boggling strength-to-weight ratio of carbon fiber results in a lighter hull, leading to lightning-fast acceleration and jaw.

Carbon Fibre Q90 4Section Tripod

In high-tech applications requiring high strength and stiffness combined with light weight, our carbon fiber-reinforced plastic (CFRP) components are indispensable. The properties of CFRP materials bring to bear precisely when other materials reach their limits. CFRP is considerably lighter than aluminum or steel, while being extremely durable.

Carbon Fiber Manufacturing How It's Made SMI Composites

Carbon fiber-reinforced composite proved to be the material that better withstood the marine. environment: carbon fiber composite showed after 10 months the lowest percentage of dirt sedimented.

Reality You Need Carbon to DeCarbon ENERGYminute Energy News, Top Headlines, Commentaries

Multitude of benefits Devising a competitive production platform was only a step on the way to developing the full potential that carbon fibre composites can offer the marine industry. The impressive strength-to-weight ratio of carbon fibre composites permits the design of extremely light but strong products compared to the considerably heavier structures made from metals.

Corebon developed a new method to produce carbon fibre components YouTube

Carbon fiber/epoxy can be used in applications requiring even lighter weight to increase speed or fuel efficiency, such as in sailing boats or racing boats. More recently, new international regulations have allowed developments in composite decks, superstructures, rudders and other components for large ships as well.

Carbon Fibre Manufacturing Specialists Carbon Fibre Composites Ltd

In comparison to aluminium products, carbon fibre and GRP composites provide generous weight savings as well as increased fatigue resistance and stiffness. In recent years the use of composites has revolutionised the marine industry, with the risk of common issues like rotting and corrosion significantly reduced courtesy of the environmental.

Carbon Fibre Manufacturing Specialists Carbon Fibre Composites Ltd

Global marine composites market size will increase to $1.6bn by 2025, up from $1.1bn in 2019. 2.79 x wind speed. Boats using carbon fibre, composite and polymer components can travel at 2.79 x wind speed. If you need lightweight composite manufacturing for the marine industry, we can help you.

CF Composites Bespoke Engineering Carbon Fibre Manufacturing England

Fiber Reinforced Plastics (FRPs) are widely used in marine sector owing to their high specific strength and resistance to marine corrosion. For naval application, additional advantages are transparency to radar wave and better vibration damping than metals. The use of various FRPs in off-shore structures and marine vessels needs analysis of desired properties considering the types of matrices.

Carbon Fiber the wonder material explained FuroSystems

An innovative alternative to fiberglass, epoxy carbon fiber is stronger, lighter and has many additional benefits that make it a real advantage for the boating industry as well as offshore oil rigs and energy development. For companies looking for innovative solutions, ESE is an ideal partner. Our use of tailored fiber placement (TFP.

- Amazon Me Indica Que He Devuelto Un Articulo

- Heladería La Cremería Gelato Italiano Reseñas

- Emergency Denture Repairs In Slough

- Ley De Inflación Estados Unidos

- Juegos Para Educación Física Sin Material

- La Pera Baja La Presion

- La Virgen De La Nieve

- Venta De Casas En Valdoviño

- Facebook Muebles Hermanos Lopez Santiago

- Los Equipos De La Liga